The Round Neodymium Magnet Rod delivers exceptional magnetic strength in a durable cylindrical design. Perfect for precision applications, it offers high holding power and longevity, making it ideal for use in chemical processing, food industry, waste recycling, carbon black production, and other diverse fields requiring reliable magnetic solutions.

Material :

NdFeB MagnetOrder(MOQ) :

1 pcsProduct Origin :

Jiangsu, ChinaShape :

Round TubeLead Time :

Within 7 daysGrade :

8000-14000GSRound Neodymium Magnet Rod

Magnetic rods are mainly used in magnetic separators composed of magnetic frames, which can effectively remove iron impurities and small metal particles in loose or flowing raw materials.

Huajin Magnet provides custom round magnet rods in different shapes, available in a wide range of sizes and materials.

Product Details

| Type | Permanent Sintered Neodymium Magnet Rod / Rare Earth Magnet Rod |

| Material | Neodymium Magnet+SUS304/316L Pipe |

| Shape | Round |

| Working Temperature | 80ºC~200ºC |

| Size | Customized according to customers’ requirements |

| Casing | SUS304/316L |

| Dimension | Dia: 16mm, 20mm, 22mm, 25mm, 28mm, 30mm, 32mm,50mm ect. |

| Application | Industrial filter, food industry, Ceramic industry ect. |

| Delivery date | 7-10 days |

How to Design the Size of Magnetic Rod?

1. Diameter: According to the following table, different diameters correspond to different Gauss value. Select the appropriate diameter.

| Diameter | 6000GS | 7000GS | 8000GS | 10000GS | 11000GS | 12000GS | 14000GS |

| Ø16 | √ | ||||||

| Ø20 | √ | √ | √ | √ | |||

| Ø22 | √ | √ | √ | √ | |||

| Ø25 | √ | √ | √ | √ | √ | √ | √ |

| Ø28 | √ | √ | √ | √ | √ | √ | |

| Ø30 | √ | √ | √ | √ | √ | √ | √ |

| Ø32 | √ | √ | √ | √ | √ | √ | |

| Ø50 | √ | √ | √ | √ | √ | √ | √ |

*recommended diameter is Ø25mm(1″)

2. Length: Any length can be customized within 10-1000mm.

3. Ends type:

smooth end pressed edge thread hole external thread countersunk end

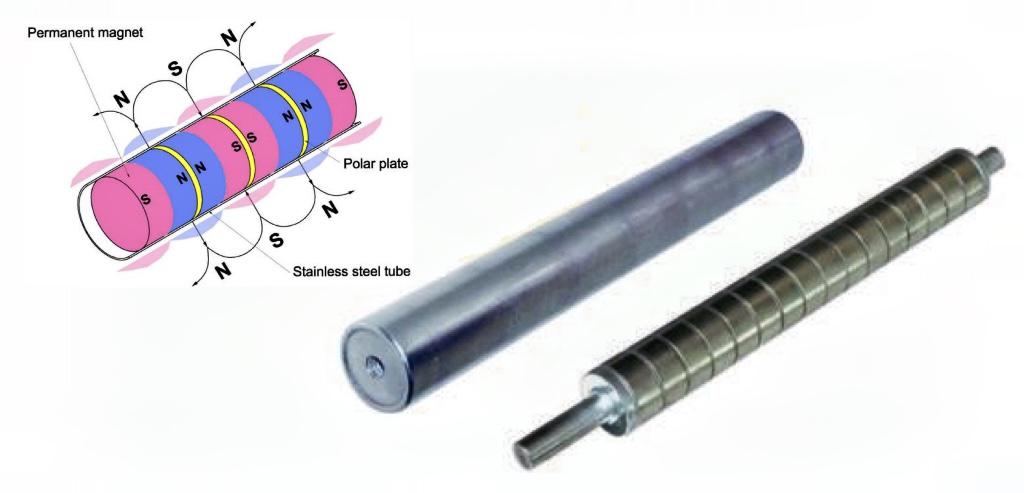

Magnetization Direction

Magnetic rods use strong magnetic fields generated by embedded neodymium magnets to attract and capture ferromagnetic particles, such as iron or steel. Encased in stainless steel, these rods are commonly used in industries like food processing, chemical manufacturing, and recycling to ensure product purity by removing metal contaminants.

As materials flow past the magnetic rod, the magnetic field pulls and traps ferromagnetic particles onto the rod's surface, while non-magnetic materials continue through the process. These rods are particularly effective in liquid, slurry, or dry bulk material systems. After accumulating contaminants, the rods are cleaned by removing and wiping off the trapped particles, ensuring efficient and ongoing operation.

Package

The packaging of a magnetic rod is designed to ensure protection, safety, and ease of handling. Each rod is first wrapped in protective materials like bubble wrap or foam to prevent damage and avoid direct contact between magnets, which could cause them to snap together.

For stronger magnets, magnetic shielding materials, such as metal sheets or specialized bags, are used to contain the magnetic field and prevent interference with nearby objects. The wrapped rods are then placed in individual boxes for added security.

These are grouped together in a larger, reinforced carton with cushioning, such as foam inserts or packing peanuts, to absorb shocks during transit.

Application

Attraction of Ferromagnetic Particles: As materials or substances containing ferromagnetic particles (like iron) pass near or through the magnetic rod, the magnetic field exerts a force on these particles, pulling them toward the rod and trapping them on its surface.

Separation Process: In industrial applications, magnetic rods are often used in liquid, slurry, or dry bulk material processing systems. As the material flows past the magnetic rod, ferromagnetic contaminants are captured and held by the rod, while non-magnetic materials continue to flow through.

Cleaning and Maintenance: Once the rod has accumulated enough ferromagnetic material, it needs to be cleaned. This is typically done by removing the rod from the flow and manually or automatically wiping off the collected particles. Some systems are designed with easy-cleaning mechanisms to facilitate this process.

Magnetic rods are commonly used in industries such as food processing, chemical manufacturing, and recycling, where they help ensure product purity by removing unwanted metal contaminants.

Copyright @2024 Nanjing Huajin Magnet Co., Ltd. All Rights Reserved.

Sitemap

/ Blog

/ Xml

/ Privacy Policy

Network Supported

Network Supported