Neodymium Arc Segment Magnets are curved magnets in different shapes. They are a unique shape because of the limits of magnetization orientation. They will combine to form a ring magnet instead of single radial ring magnets.

Material :

NdFeB MagnetOrder(MOQ) :

100 pcsProduct Origin :

Jiangsu, ChinaShape :

ArcLead Time :

Within 15 daysGrade :

N35-N52,(M,H,SH,UH,EH,AH)Neodymium Arc Segment Magnet

The neodymium arc segment magnet is engineered for applications that require a strong, focused magnetic field in a curved shape. Typically used in motors, generators, and magnetic assemblies, these magnets are made from high-quality neodymium, offering exceptional magnetic strength and durability. Their arc shape allows for seamless integration into rotor assemblies, optimizing performance in electric vehicles, wind turbines, and various industrial machines. With their ability to provide consistent magnetic force, Neodymium Arc Segment Magnets enhance the efficiency and power output of devices, making them an essential component in modern engineering and technology. Whether for commercial or DIY projects, these magnets deliver reliability and high performance in demanding applications.

Product Details

| Type | Permanent Sintered Neodymium Magnets / Rare Earth Magnet |

| Material | NdFeB |

| Shape | Arc |

| Size | Customized according to customers’ requirements |

| Coating | Ni, Zn, Epoxy, Parylene, Gold, Passivated, etc |

| Density | 7.5-7.6 g / cm³ |

| Delivery date | 2-4 days for common samples, 7-10 days for mass production |

What grades & shapes are available for neodymium magnets?

Grades N35, N38, N40, N42, N48, N50, and N52 ( M, H, SH, UH, EH, AH series ) are available for all shapes & sizes of NdFeB magnets.

|

Magnetic Grade

&

Working Temperature

|

Magnetic Grade | Working Temperature |

| N35-N52 | 80℃ (176℉) | |

| 38M-52M | 100℃ (212℉) | |

| 35H-50H | 120℃ (248℉) | |

| 33SH-46SH | 150℃ (302℉) | |

| 30UH-42UH | 180℃ (356℉) | |

| 30EH-38EH | 200℃ (392℉) | |

| 28AH-33AH | 230℃ (428℉) |

Magnetization Direction

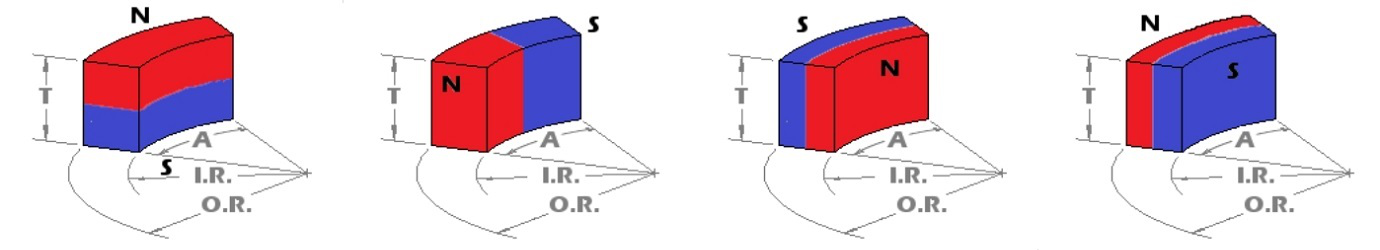

Common direction of magnetization showed in picture bellow:

Thickness Magnetized Circumference Magnetized SN Diametrically Magnetized NS Diametrically Magnetized

Grade & Coating

Support all magnet plating , like Ni-Cu-Ni, Zn, Epoxy , Gold, Silver etc.

To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated.

Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes magnets much more durable than the more common single nickel plated magnets.

Application

Neodymium magnet arcs are primarily utilized in permanent magnet motors. They have an arc shape and can be magnetized spontaneously, which makes them an important component in the manufacturing of motors. Neodymium magnet arcs have a wide range of applications, including electric vehicle motors, industrial electrical equipment, automotive electrical systems, and more.

In electric vehicle motors, neodymium magnet arcs are typically utilized in the form of permanent magnet DC motors, which are highly efficient and lightweight, making them ideal for various electrical equipment.

Additionally, neodymium magnet arcs are employed in the production of DC motors, which are essential in industrial and automotive electrical systems, including reduction motors, servo DC motors, and starter motors for automobiles and motorcycles.

Copyright @2024 Nanjing Huajin Magnet Co., Ltd. All Rights Reserved.

Sitemap

/ Blog

/ Xml

/ Privacy Policy

Network Supported

Network Supported